Quantify Grip Force by "GRIP MASTER"!

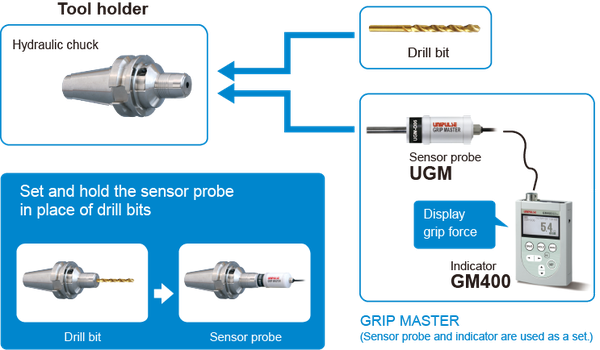

A hydraulic chuck is…

a tool holder that clamps tools used for metal cutting works to machining centers and milling machines.

Why does grip force need to be checked?

Chucks with lower gripping force may cause not only to lower machining accuracy, but may cause cutters to fall off and be flown off in the worst-case scenario.

GRIP MASTER supports daily maintenance for machine tools by measuring grip force of hydraulic chucks.

Why does grip force decrease?

The reasons could be as follows:

| ✔ Aged degradation. |

| ✔ Oil leakage from inside. |

| ✔ Damage on chuck part. |

| ✔ Dust infiltration. |

How has grip force of tool holders been managed conventionally?

Most users do not manage grip force of tool holders in the first place. In the meantime, some users check tool holders by inserting a test mandrel and applying torque until the mandrel starts slipping.

Then, what is disadvantages of the management by slip torque?

There is a risk of damage as force is applied from direction not originally intended. In addition, the direction of force applied is different from originally intended, thus the check is not accurate.

There are reasons why GRIP MASTER is a perfect grip force checker!

GRIP MASTER can be used by simply inserting the sensor probe to tool holders, in place of a drill bit. What's more, GRIP MASTER can check and manage tool holders with force applied to right direction!

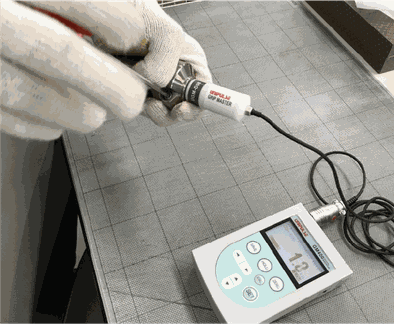

The console of GRIP MASTER is capable of displaying measured value in real-time and data recording.

Recorded data can be easily exported to PC.

The sensor probes of 11 different diameters (φ4, 5, 6, 7, 8, 10, 12, 16, 20, 25 and 32mm) are available.

Dedicated carrying case is included.