Weighing Indicator for checker scale F650-CK

For all sorts and weighing such as food processing machines and fruit sorters.

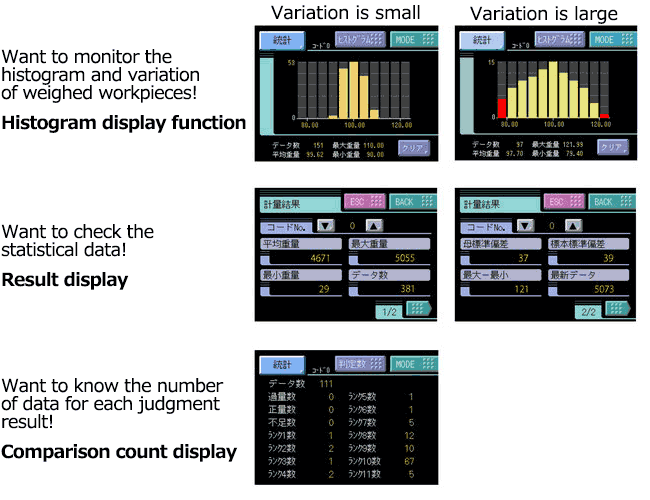

Easily check data variations with the histogram display!

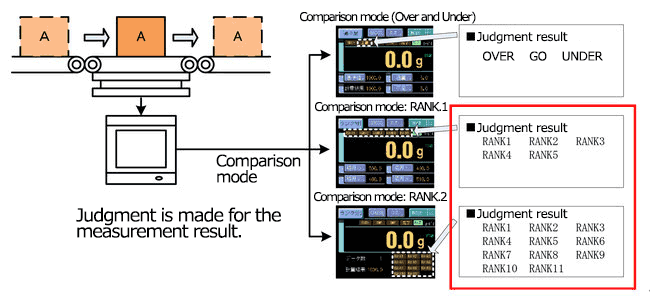

Point #1: Abundant judgment modes

Sorting by weight up to 11 ranks.

Point #2: Real-time statistics

Distribution of ranks can be checked in one glance with the histogram display.

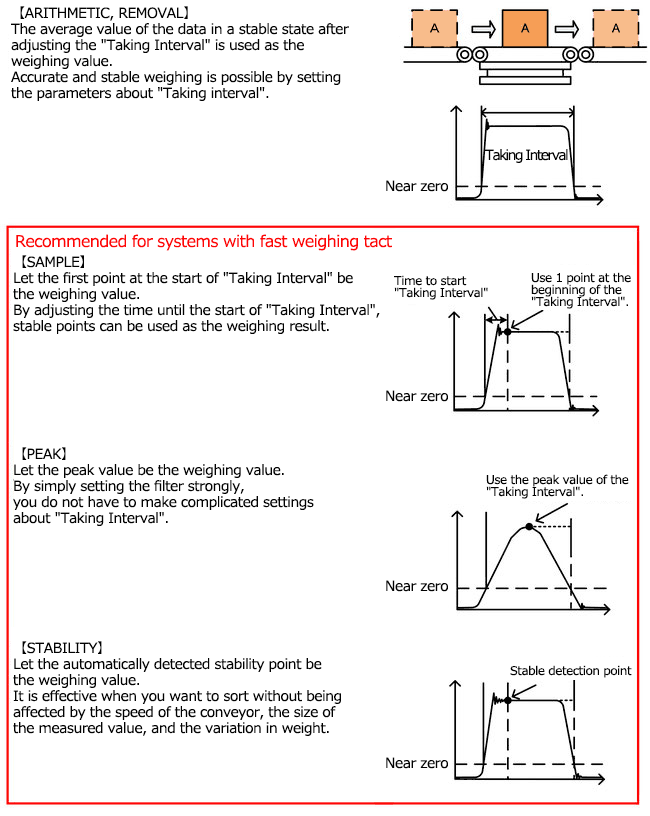

Point #3: Useful weighing modes to improve efficiency & accuracy

Weighing mode suitable for your equipment can be selected from various options.

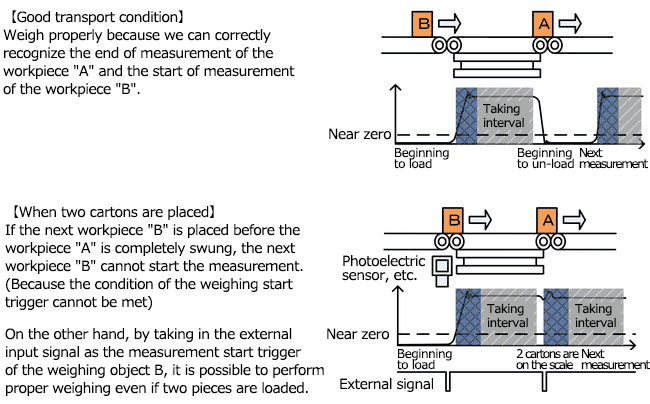

Point #4: Detect the situation when two cartons are on the scale.

"Two cartons are on the scale" usually makes the weighing difficult.

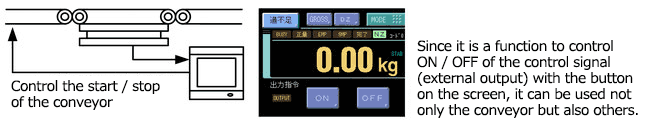

Point #5: PLC-less conveyor control

Peripheral devices can be controlled without PLC.

Point #1: Abundant judgment modes

You can perform OK / NOK judgment (comparison of OVER and UNDER) to see if the weight of the weighed workpiece is within the specified value, and sort by weight.

You can set ranks up to 11 ranks.

Point #2: Real-time statistics

Weighing results can be accumulated and statistically processed. You can easily check the variation and statistical data of your weighing system with this one unit.

Point #3: Useful weighing modes to improve efficiency & accuracy

Supports various situations with various weighing modes.

In addition, a full range of functions improve weighing efficiency and accuracy.

- Trigger mode to start sampling.

You can select the trigger mode to start the measurement from the following two.

【Level】 Weighing starts when the weight exceeds near zero.

【External】 After start signals are input from the external and weighing starts when the weight exceeds near zero. - Hold operation of weighing result

When the weighing mode is 【SAMPLE】 or 【STABILITY】, the indicated value can be held at the time of weighing judgment. In addition to selecting whether to hold or not, you can also release the hold the next time weighing starts during the hold. Use the hold function properly according to the situation at the site. - Perform zero correction while operating

When sorting food products, the zero point is likely to shift due to the effects of deposits remaining on the conveyor and air resistance due to temperature control. This indicator can also find an appropriate point and automatically perform zero correction.

Point #4: Detect the situation when two cartons are on the scale.

"Two cartons are on the scale" means that two or more objects are placed on the part that detects the load. Normally, if two cartons are placed, it will not be possible to measure properly.

Point #5: PLC-less conveyor control

Also, if the judgment result is NOK (Under or Over), it can be used sequentially such as turning off the output of the control signal.

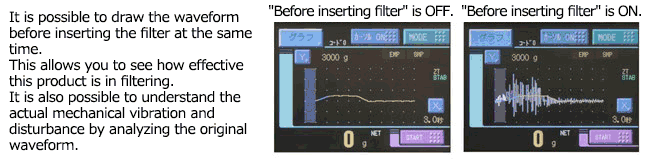

Graphic mode

In addition, the display can be drawn retroactively for the set ratio time with respect to the start of graph drawing.

If the trigger near zero is staggering, it may cause malfunction, but you can pick up such a part and clearly check the unstable time.

High-performance filter eliminates vibration

A high-performance filter that removes vibration noise has achieved stable and accurate weighing. In addition, since detailed digital settings can be made, it is easy for customers to make on-site adjustments in addition to the graph function.

Compact design

The front panel has a compact design of DIN 96 (W) x 96 (H).

Standard interface and Optional interface

RS-232C and SI/F are equipped as standard. One optional interface can be added in addition to the standard interface from below.

- BCD parallel data output

- D/A converter (voltage output)

- D/A converter (current output)

- CC-Link interface (Available for Ver.2)

- DeviceNet interface

Also supports dustproof and waterproof

The following optional items are available separately.

- Dustproof: Rubber seal

- Waterproof: Waterproof cover (Manufactured by OMRON)