Torque sensor UTMIII (C) type: New concept for installation

What's the advantage of UTM series? Its structure is composed of light-weight housing dangling on the shaft by the two bearings, and torque applied at the rotating shaft can be measured accurately as frictions on the bearings are quite minimal.

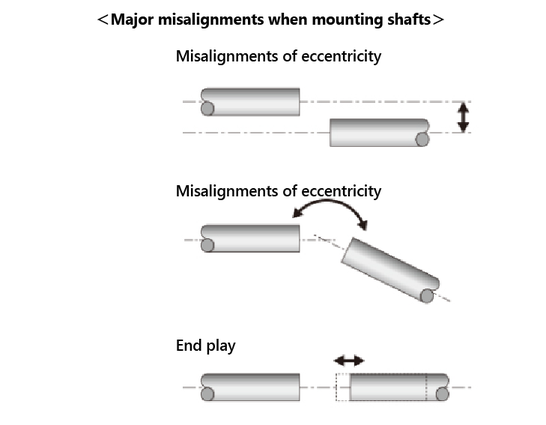

When the housing of UTM series is fixed, a force is easily applied at the bearings between the shafts and the housing due to misalignments. If a force is applied at the bearings, a frictional force against rotation will increase, and it ends up with affecting the accuracy.

Due to the reasons, normally the installation method which does not fix the housing of UTM is recommended.

\\\ Read more about UTM installation method without fixing the housing! ///

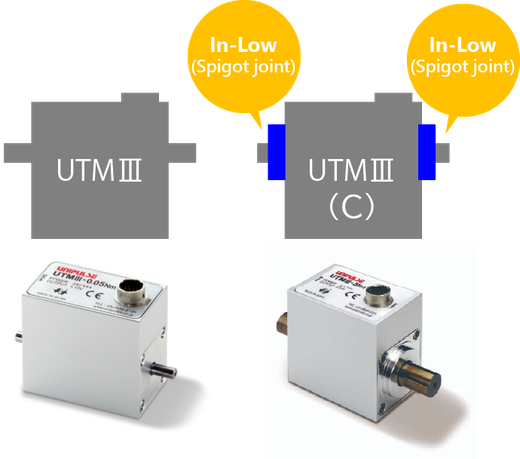

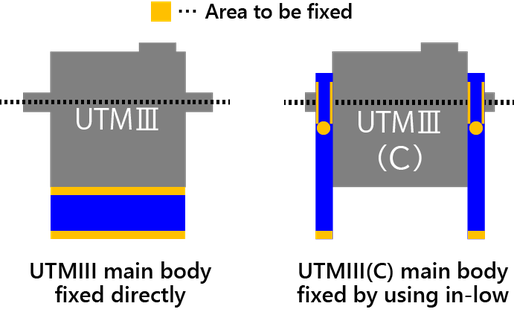

UTMIII(C) series is a model with the housing of UTM allowed to be fixed with high accuracy.

Compared with the regular UTMIII, UTMIII(C) is equipped with 3mm projection parts called "In-Lows", as you can recognize by appearance.

These parts called "In-Low" (that is, spigot joint) are the secret for fixing the housing!

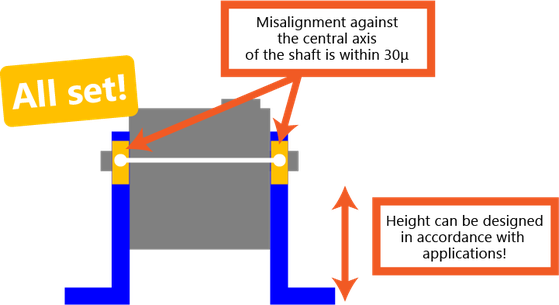

The error between the central axis of the in-lows and the central axis of the shaft is adjusted within only 30μ. Moreover, force is hardly applied at the bearings even if the in-low parts are fixed. Thus, accurate torque measurement can be performed.

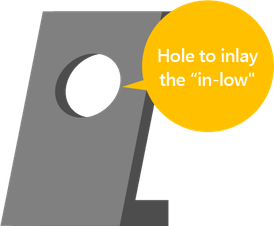

Design and produce a jig to inlay the in-low part…

…and it's now ready to go!

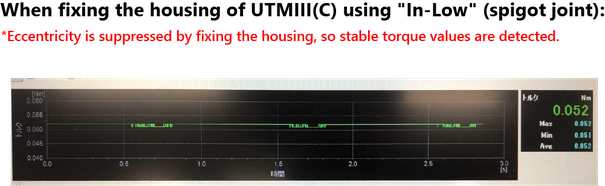

What is the merit of fixing UTMIII(C) by "In-Low"?

● Eliminate factors of misalignment

When fixing the bottom face of UTM, what matters is

a machining and an assembling accuracy between the housing

and the bearing cases as well as the housing and the mounting

side.

In the meantime, with "In-Low" type the center of the in-low

and the bearings can be accurately adjusted.

By fixing the in-low parts, influence of a machining and

an assembling accuracy between the housing and the bearing

cases as well as the housing and the mounting side can be

excluded. Therefore, high precision installation with little

misalignments can be achieved.

Compared UTMIII & UTMIII(C) by using Oldham couplings!

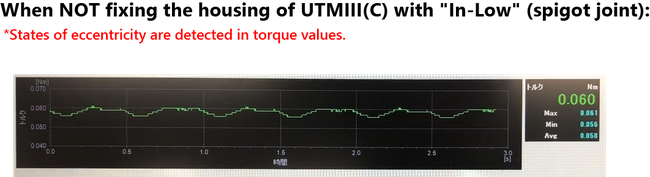

#1. Demonstration of UTMIII with Oldham couplings

#2. Demonstration of UTMIII(C) "In-low" type with Oldham couplings

#3. Comparing 3 different kinds of couplings: Vibration-proof type, Slit type & Oldham type

While there are several kinds of couplings that can be used for UTM series, here are the recommended combinations of couplings for each case:

- When NOT fixing the housing, "Rubber couplings on both sides",

or "Single Disc couplings on both sides" are recommended. - When fixing the housing (including "In-low" type), "Double Disc couplings on both sides" are recommended.

*"Single Disc couplings on both sides" are NOT recommended.

Newsletter Archive: UTMIII Topics

This newsletter is delivered to those who use or consider UNIPULSE products.

If you have any questions or concerns regarding products, CONTACT US from the inquiry form below.