Do you measure a clamping force on a main spindle of a machining center?

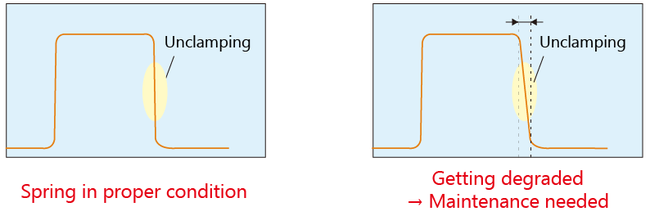

A Belleville spring on the drawbar part of the main spindle does have a lifespan. When it is degraded, it affects the machining accuracy.

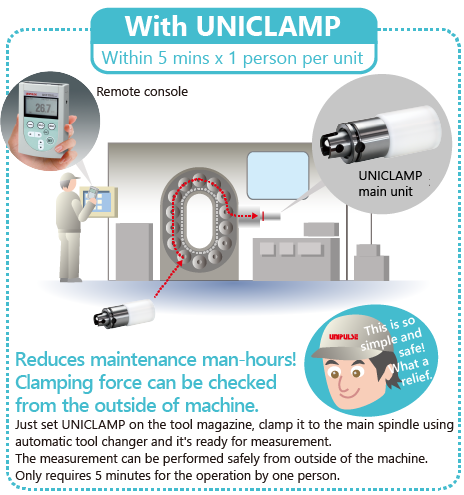

Manage the main spindle with Clamping Force Tester UNICLAMP!

Easy to handle! Easy check even by single-person operation

Clamping force can be measured at not only when clamping but also when unclamping!

From the way it degrades when unclamping, the lifespan of the Belleville spring on a main spindle can be found instantaneously.

Take a look at an actual scene of a measurement!

Tool holders do have lifespans.

Even if a tool is set with a holder in the same ways as usual, the tool holder is not necessarily holding the tool with the same gripping force.

Grip force may decrease due to hydraulic oil leakage or lifespan, and as a result, it may cause reductions in processing accuracy or tools to fall.

Check tool holders with Grip Force Tester GRIP MASTER!

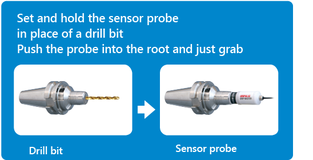

No calibration needed! Just connect and ready for measurement!

The sensor probes of 11 different diameters from φ4, 5, 6, 7, 8, 10, 12, 16, 20, 25 and 32mm are available. As the calibration data is recorded inside the probes, GRIP MASTER can be used immediately by connecting it.

Just grip a sensor instead of a tool!

Can be used with other diameters too with dedicated adaptors. (Inch diameter also supported.)

Compatible with hydraulic chuck / collet chuck / milling chuck. (Dedicated adaptors are needed for a collet & a milling chuck)

Take a look at an actual scene of a measurement!

Isn't adjusting oil pressure on lathe machine now becoming too much craftsmanship?

Having difficulties finding conditions of suitable chucking force for each workpiece?

Easy maintenance with Chucking Force Tester UNICHUCK!

Measurable even during rotation! Measurement can be performed in a condition near the actual operating condition

Easy chuck adjustment on thin workpiece!

Effective for not only monitoring on a fatigue of a chuck, but also for finding conditions on processing.

When clamping a thin workpiece strongly, it deforms; when clamping it softly, it would slip during processing. With UNICHUCK, it measures gripping force by rotation speed during processing and enables to adjust oil pressure.

Supporting two-jaw / three-jaw / collet chuck!

We can flexibly support a special chuck too as a special order. Do ask us.