Product outline

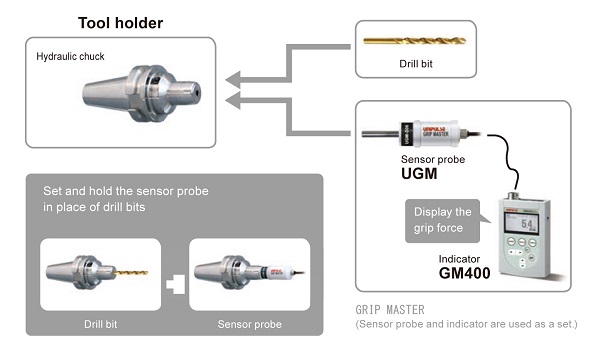

GRIP MASTER is a tool to quantify grip force in metalworking, while measuring and managing a stabilized metalworking process.

Grip force of drill bits or work can be properly managed, preventive maintenance of machine tools, improvement of machining quality are made possible.

Huge line up of sensor probe from φ4 to φ32 are available, besides that various functions such as memory function ensures an easy management of grip force.

Safe and easy inspection with quantified grip force

Grip force of tool holders can be easily checked by simply inserting and gripping the sensor probe by a tool holder.

Did you know that tool holders also have lifespan?

It does not mean that the same grip force is applied always, even if tools are set in a usual way.

Gripping force of tool holders changes over time due to wear and over use. Especially, gripping force of a hydraulic chuck declines over time depending on usage.

Then, if not enough grip force is applied, it may lower machining accuracy and may cause damage on products, lowering productivity a lot.

■By checking the grip force of tool holders, you can…

1)check if enough force is applied to hold bits.

2)detect deterioration of tool holders in advance

▼

■Prevent damage and problems during metalworking process!

A variety of sensor probe product lines

φ4 to φ32 supported

Ideal for hydraulic chuck

Gripping force of tool and work holders can be checked regularly to maintain the runout accuracy.

No calibration required

Information of the sensor is stored in the memory of the sensor probe itself.

There is no need to enter information for calibration each time when a sensor probe is changed.

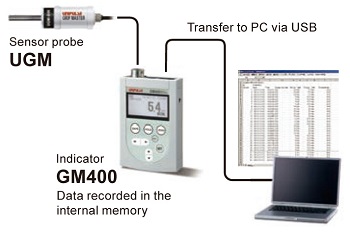

Easy data recording by pressing “SAVE” button

Measurement data will be recorded with date and time when “SAVE” button is pressed.

Recorded data can be easily exported to PC via USB interface.

Carrying case

Specifications

|UGM:Sensor probe|GM400:Indicator|

| UGM:Sensor probe(φ4, φ6, φ8, φ10, φ12, φ16) | |||||||||

| Model | UGM-D04 | UGM-D05 | UGM-D06 | UGM-D07 | UGM-D08 | UGM-D10 | UGM-D12 | UGM-D16 | |

|---|---|---|---|---|---|---|---|---|---|

| Diameter | 4 mm |

5 mm |

6 mm |

7 mm |

8 mm |

10 mm |

12 mm |

16 mm |

|

| Rated capacity (Grip pressure) | 140.4 Mpa |

79.6 Mpa |

124.3 Mpa |

106.6 Mpa |

93.3 Mpa |

101.6 Mpa |

83.8 Mpa |

91.8 Mpa |

|

| Rated capacity(Grip force)*1 | 10 kN | 20 kN | 40 kN | 60 kN | |||||

| Calculated slipping torque at R.C*2 | 15.0 Nm |

18.8 Nm |

45.0 Nm |

52.5 Nm |

60.0 Nm |

150.0 Nm |

180.0 Nm |

360.0 Nm |

|

| Sensing length | 17 mm |

24 mm |

25.6 mm | 37.6 mm | 38 mm |

39 mm |

|||

| Maximum safe overload |

120% R.C.

|

||||||||

| Safe temperature range |

+10 to +40℃

|

||||||||

| Cable |

φ3 shielded cable 1.5 m connector included

|

||||||||

| Material |

Sensor probe:stainless

Cover:polyacetal (it cannot be removed) |

||||||||

| Weight (excluding cable) | Approx. 100 g | Approx. 120 g | Approx. 150 g | Approx. 220 g | |||||

| UGM:Sensor probe (φ20, φ25, φ32) | ||||

| Model | UGM-D20 | UGM-D25 | UGM-D32 | |

|---|---|---|---|---|

| Diameter | 20 mm | 25 mm | 32 mm | |

| Rated capacity(Grip pressure) | 108.5 Mpa | 83.0 Mpa | 86.5 Mpa | |

| Rated capacity(Grip force)*1 | 100 kN | 150 kN | 200 kN | |

| Calculated slipping torque at R.C*2 | 750.0 Nm | 1406.3 Nm | 2400.0 Nm | |

| Sensing length | 44 mm | 69 mm | ||

| Maximum safe overload | 120% R.C. | |||

| Safe temperature range | +10 to +40℃ | |||

| Cable | φ5 shielded cable 1.5 m connector included | |||

| Material | Sensor probe:stainless Cover:polyacetal (it cannot be removed) |

|||

| Weight (excluding cable) | Approx. 360 g | Approx. 800 g | Approx. 1000 g | |

*1 Grip Force (N) = Grip Pressure (Pa) × (Radiuss (m) × Sensing Length (m)) / 3

*2 Slip Torque (N·m) = Grip Force (N) × 3 × Radius (m) × Friction Coefficient (0.25)

| GM400:Indicator | |

| Analog | |

|---|---|

| A/D converter | 80 times/sec. | Display |

| Display unit | 128 × 64 dot LCD |

| Display value | 2 decimal places + sign |

| Display contents | Switchable numeric display (grip pressure / grip force / slip torque) |

| Recorder | |

| Recording function | Record when [SAVE] is pressed |

| Recording media | Internal memory |

| Recording method | Texts in CSV format |

| Recorded data | ID, sensor number, date and time, indicated value/reading (grip pressure / grip force / torque), unit, and temperature |

| Memory for recorded data | 8,000 data |

| Function | |

| Hold | Sample/ peak |

| Interface | |

| USB interface | |

| General specifications | |

| Internal power supply | AA alkaline batteries or nickel metal hydride batteries (4 pcs.) |

| External power supply | AC adopter for 100 Vac (sold separately) |

| Max. continuous operating time | Approx. 30 hours (when backlight is off) |

| Operating conditions | Temperature: -10 to +40 ℃ Humidity: 80% RH or less (non-condensing) |

| External dimensions | 86(W) × 132(H) × 30(D) mm (Not including protrusions) |

| Weight | Approx. 290 g (including the 95 g weight of battery) |

| Attachments | |

| AA alkaline battery……4, Operation manual……1 | |

| Optional accessories | |

| AP0516:Special AC adapter (for AC 100 V) CA81-USB:1.8 m miniUSB-computer USB cable |

|

Please note that there are possibilities of individual differences in a color tone on display devices such as LEDs, fluorescent display tubes and LCDs due to manufacturing process or production lots.

Download

|

Product catalogue(PDF)

|

⇒Download Page | |

|---|---|---|

|

Operation manual(PDF)

|

||

|

External dimension

|

DXF

(ZIP) |

|

|

PDF

|

||

|

Support tools

|

||

|

Software

|

||