Want to measure load and torque for quality management!

But...

- It is too narrow so that the sensor cannot be placed.

- Because the measurement part moves, the cable gets in the way.

- I want to measure force to be applied to the workpiece but want to avoid the change of equipment.

Customized sensors will solve those problems!

Watch the video below:

By producing sensors with the same shape as the workpieces, they can be utilized in a great deal of applications such as the periodical check of existing equipment or the adjustments at the shipment of machinery.

By 100 times/sec sampling, even force transition can be measured.

Data logging as well as transferring and managing data to PC or PLC are possible.

For example, small-size digital load cells, torque meters and more…

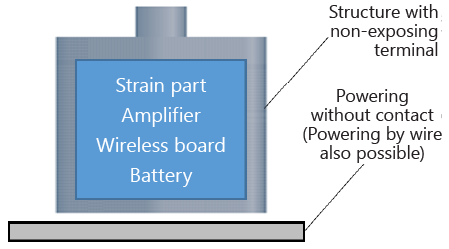

Ultra-compact amplifier & wireless board

Small-size battery

Strain part (Strain gauge)

Even supports

compact-size!

Specification of this example:

Ideal for such applications as well:

- Compact-size thus it can be placed in a narrow spot!

- Power supply cable is unnecessary due to battery driven!

- The structure with a non-exposing terminal is possible too!

With a structure with a terminal that is not exposed, simple sterilization is also possible!

Even a sensor with the main body weight of only 20 g can be produced.

For a periodical check of cappers or press machines

Above: an example of a capper check.

The sensor can perform measurements while being put in the production line with actual products.