Torque is a twisting force to rotate objects. Although it is not familiar for some of you, torque is very essential parameter in our life. It is getting more familiar as we use more and more actuators like motors for industrial automation nowadays.

Many products around you use rotating parts, and forces that attempts to rotate and to prevent it from rotating are generated there. On this page. we explain about the basics of torque and introduce torque meters.

What is torque?

Torque is twisting force to rotate shafts and other objects.

Putting it simple, torque is a force to rotate a shaft and a reaction force to stop the motion.

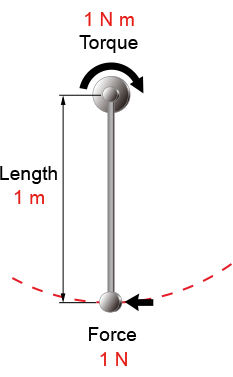

Torque is force that tends to rotates shaft, and it can be calculated with force and distance from a pivot point.

The torque which is applied at in the right picture can be calculated as below:

for torque.

Various torque meters

There are various torque meters, and each type has advantages and disadvantages.

| Non-rotary type (Static torque) | |

| Strain gauge | Non-rotary type (e.g. torque wrench) |

| Rotary type (Dynamic torque) | |

| Magnetostriction | High rated rotational speed, but not so accurate |

| Strain gauge | High-accuracy, but difficult to transmit signal from rotating shafts |

| Differential phase | Large in size due to the mechanical structure |

as long as UTMⅢ is selected.

Since production lead time is short, there is not much risk to use it in production line as well.

Our product lines include couplings and torque monitoring instruments.

Please feel free to ask us such as torque control, measurement, and so on.

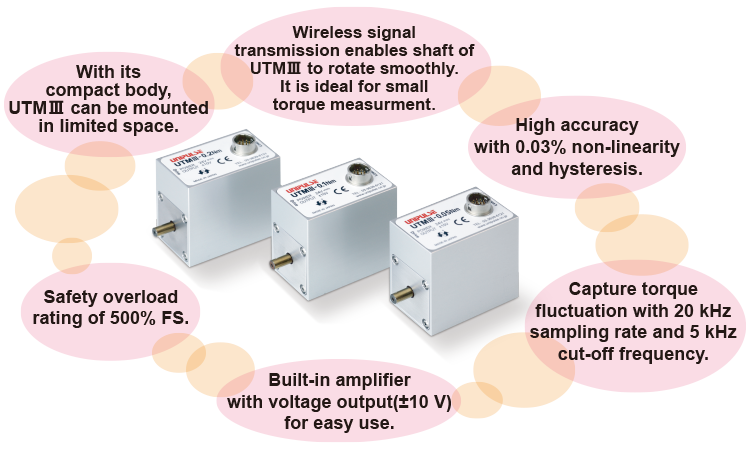

Where are torque meters used?

Torque meters are used in many applications, but it can be divided into R&D purpose and in-line product quality control purpose.

Click the product names to see the product details.

TM700 High-Speed Torque Waveform Monitor

Waveform display of torque, rotation speed and power over time

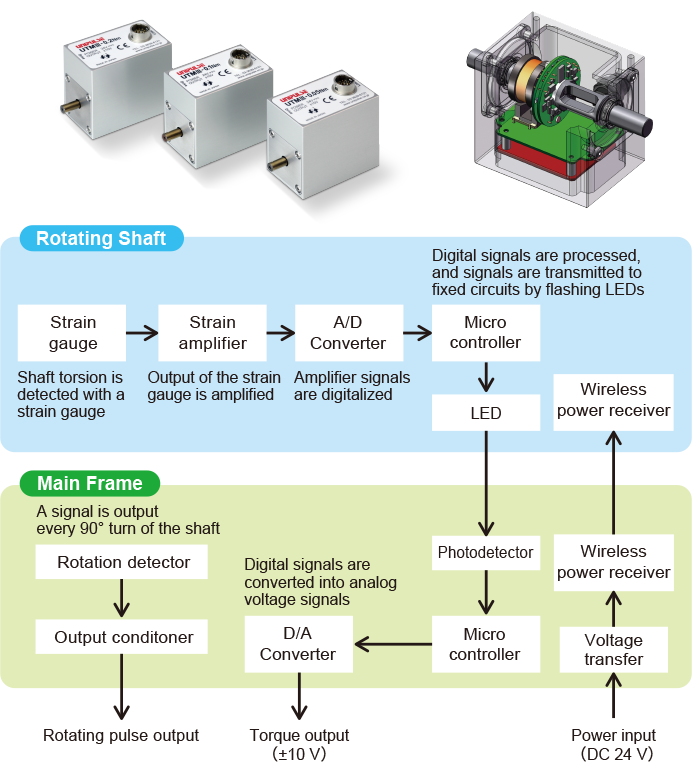

What are the benefits of contactless transmission?

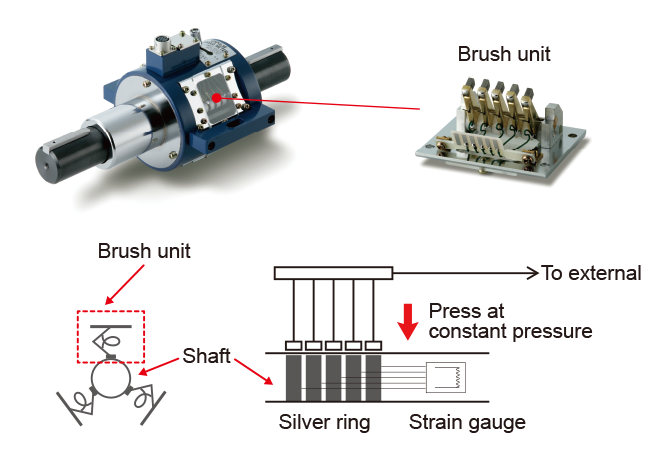

In conventional rotary torque meters, the sensor output is extracted from the rotating object by pressing multiple slip rings against the shaft. There were some major problems with this, limiting the sensor specs and applications.

UTMⅢ has become an easy-to-use torque meter with high specifications, high rpm and maintenance-free through non-contact transmission.

The contact type requires regular maintenance due to wear of the carbon contactor. Also, the brush must press the shaft with constant pressure, which prevents rotation so it is not suitable for measuring low torque.

| Contactable type | |

| ・Maintenance is required. | ・Not able to perform high-speed rotation. |

| ・Low capacity type cannot be made. | ・Accuracy is bad. |

| ・Data may be interrupted. | ・Main body is big. |

Since there is nothing to hinder rotation, high accuracy is achieved. Maintenance is not required as well.

| Features of UTMⅢ |

| ・Maintenance-free |

| ・Lineups from 0.05 N m minute torque |

| ・High-speed rotation of 25000 rpm(0.05 to 2 N m) |

| ・High accuracy with compact size |

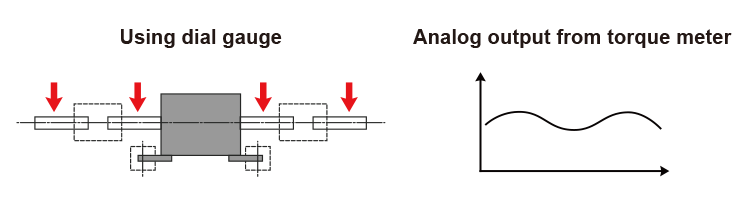

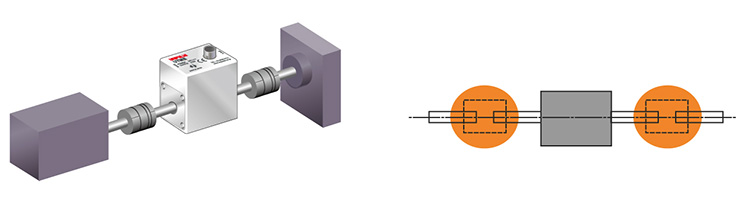

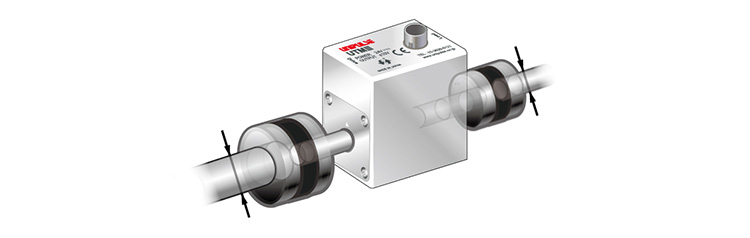

It is important to align all shafts in line when a torque meter is jointed.

Dial gauges are commonly used to check run-out. But, using analog output from UTMII, alignment can be adjusted without dial gauge indicators.

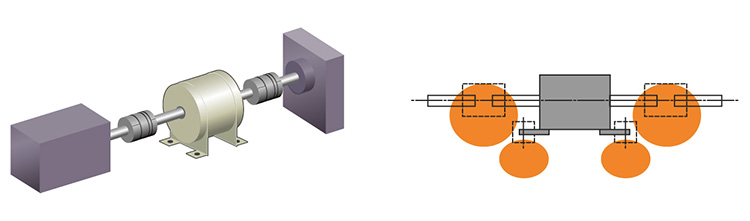

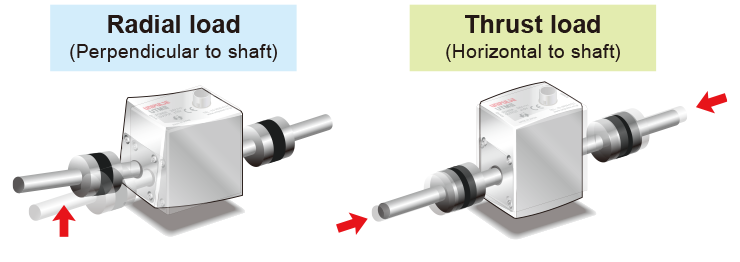

It is also important to make sure that no radial load is applied to shafts (perpendicular to shaft).

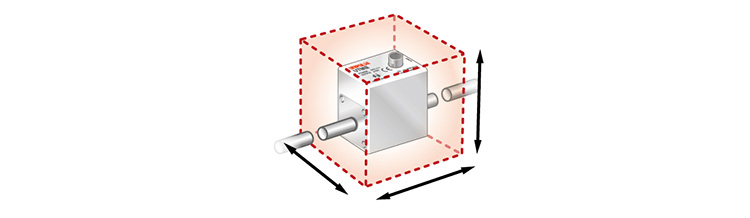

If the torque meter is too large, weight of the sensor itself may affect the measurement accuracy.

Yet, since weight of UTMⅢ is light (relative to shaft strength), it does not affect the measurement accuracy. The mounting arrangement is also simple and it can be suspended as below.

*Please take some safety measures in case the torque sensor is suspended.

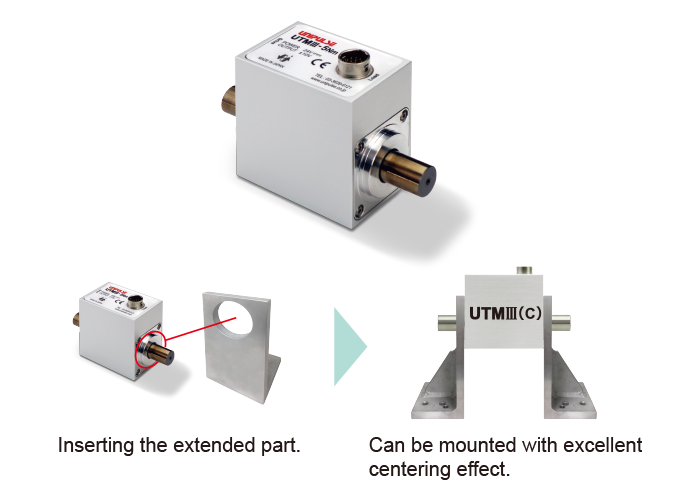

UTMⅢ(C) Rotary Torque Meter

Centering Location Type

>> Go to Centering Type Rotating Torque Meter UTMⅢ(C) Product Page

At first, please reconfirm the purpose of measuring torque. Then, please check followings as guidance for selecting proper type.

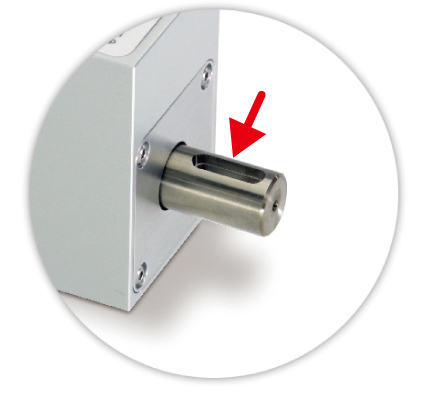

(K) Key groove

(K) Key groove (C) Centering location

(C) Centering location (R) Rotary encoder

(R) Rotary encoder (WR) Square drive + encoder

(WR) Square drive + encoder *(C) is for UTMⅢ only, (WR) is for UTMⅡ only.

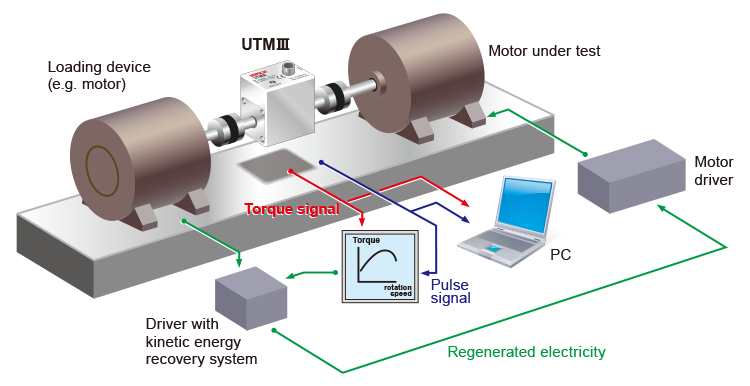

Motor Test Bench

Performance of motors is evaluated with actual load.

To put load on motors, powder brakes or hysteresis brakes are used.

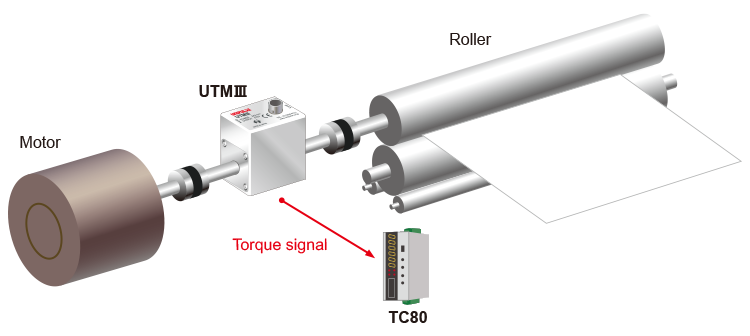

Rotary Torque Measurement of Rollers

Torque to rotate paper/sheet feed roller is measured to verify the ideal setting and conditions.

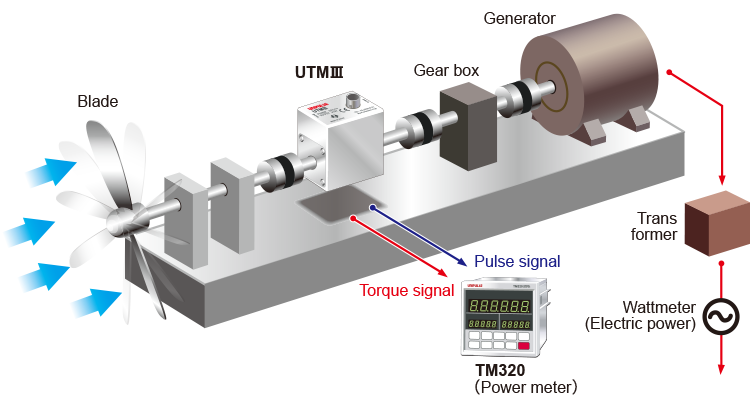

Evaluation of Power Generation Efficiency

Power is calculated based on torque and rotational speed to evaluate power generation efficiency.

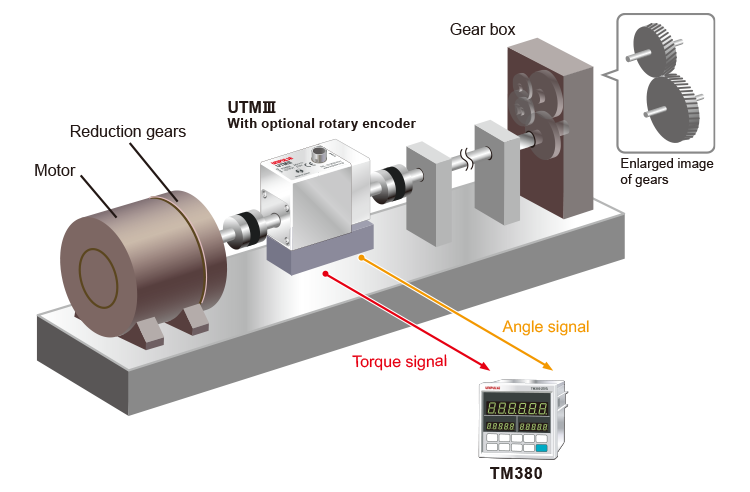

Physical sensory test

Smoothness of gear box rotation can be digitized and represented in number. Product quality can be also checked at the same time.

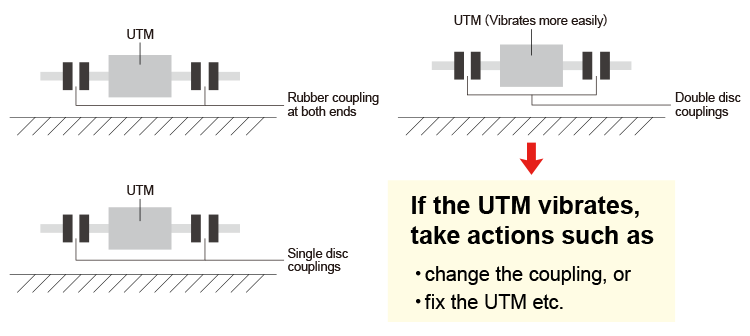

There are many different types of couplings, but not all couplings can be used with the UTM. Proper couplings for torque measurement need to be selected.

Before selecting coupling, please consider the followings:

● Couplings need to have high torque transfer capacity.

● Maximum rotation speed needs to be maintained below

the rated RPM.

Please select couplings suitable for your application.

*Use of Oldham couplings is not recommended. In case Oldham coupling needs to be used, please consult us for mounting arrangement.

*For centering location type, please install double couplings on both sides.

Our coupling product line includes rubber type couplings, which can absorb shock and vibration caused by high rotational speed or servo motor.

In case rigid couplings are required, we can offer other type as well.

Choose a coupling that does not allow the torque meter to vibrate.

When using the UTM without fixation, it is recommended to use a rubber coupling or a single-disc coupling at both ends.

Shafts of torque meters are sensing parts, and doing so will damage the product.

Please make sure that radial and thrust loads are not applied to shafts directly.

In case rotational vibration exists, oscillation in large amplitude may occurs when rotational speed approaches to the resonant frequency of the system, which in turn causes overload and severe damage on torque meters.

please stop operation immediately and take measures or change the rotational speed to prevent resonance.

Torque means torsion force which is applied on the shaft to be rotated. For example, when you use a screw driver or a wrench, torque is applied to threads, bolts and so on.

If the point of effort is farther, more torque can be applied to the point of action. Therefore, torque can be calculated by multiplying force and distance. Generally, N m, an international standard unit, is commonly used.

Newton meter is a unit for torque defined by SI. 1 N m is 1 N force in vertical direction applied on a specific point, which is one meter away from the point of effort.

While there are typical instruments for measuring torque, such as torque wrench etc, measurement is relatively easy with these instruments because only the torque at the end of the process needs to be measured.

However, there are a lot of products whose shafts transmit power continuously, such as a motor, an engine, a speed reducer and a roller. The rotating torque meter is a device which can measure torque on rotating shaft.

UTMⅢ has many great features, and we have been receiving many positive feedback from our customers.

The followings are some examples of evaluations we have received:

● The main unit is compact so can be installed in a narrow space.

● Smooth rotation and a lineup of minute torques.

● High accuracy such as non-linearity and hysteresis

● Load capacity 500% R.O. makes it resistant to overload and safe

● High bandwidth of 5 kHz and 20 kHz sampling allow it to follow fast torque variation.

● Built-in amplifier

● Competitive price

● Short lead time

RPM stands for Revolution Per Minute.

Please use DC 24V (Consumption current is 100 – 160 mA)

UTMⅢ comes with a 2 m cable. One side of the cable is connector type (to UTMⅢ), and the other is non-connector type.

In addition, if you want a 5 m cable, we have a replacement option that allows you to replace the 2 m cable and the 5 m cable.

We calibrate UTMⅢ before shipping. The voltage output is adjusted to full scale(±10 V).

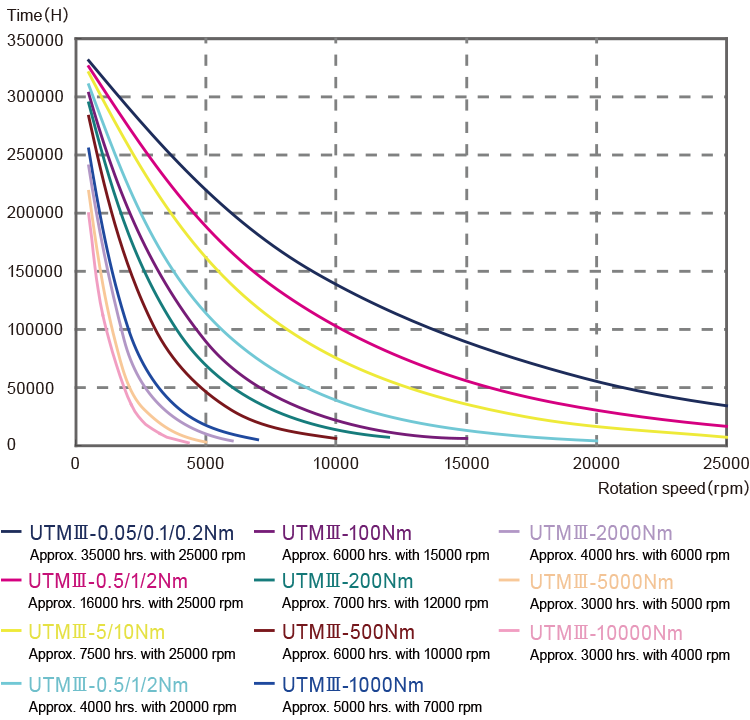

The lifecycle of UTMⅢ depends on how long the bearing lasts. Please find the life expectancy of bearings as follows.

UTMⅢ is maintenance-free product because of contact-less structure.

UTMⅢ outputs 4 pulses per revolution for RPM reading. External devices can be used to convert pulse signal to RPM.

UTMⅢ dedicated torque monitor has a built-in function to display this pulse signal as the number of revolutions (RPM).

The overload capacity of UTMⅢ is 500% R.O. Even the momentary load above the capacity will not damage the product immediately.

That depends on conditions. Please contact our sales representative.

UTMⅢ comes with the 2 m cable. If you need a special cable, please contact our sales team.

We can also sell the connectors only so that you can connect with your cable.

It is not recommended.

That may cause inaccurate measurements, or lifetime of bearing may be drastically shortened.

If you know the rotational torque and the number of revolutions, you can calculate the power.

The TC80-D3V, TC80-EIP, TM700, TM320, and TM201 have built-in automatic power calculation functions.

The power calculation formula is as follows:

Yes, you can. Please ask our sales representative at the time of order placement.

Generally a dial gage is used to adjust alignment while the shaft is being rotated slowly. At the end, check the UTMⅢ output waveform and adjust it to minimize fluctuations.

Since moment of inertia on drive and load (driven) side are different, the torque output will be slightly different as well.

So, even though it will not cause damage, please install properly.

No. Please use it under the rated capacity. The overload capacity of UTMⅢ is 500% FS for sure, but it is only for safety purpose.

There is a protection circuit in UTMⅢ, so minor error in wiring will not damage the product immediately.

(Still, input of high voltage, such as AC 100 V, will damage the products.)

TM700: 0.1 rpm

TC80-D3V, TM380, TM320 & TM201: 2 rpm

TM400: 15 rpm

If it falls below this limit, the torque monitor side is forced to display 0 rpm.

However, when the UTMⅢ and TM320 are displayed with RS-485 digital output, it can be displayed at 1 rpm depending on the setting.

Although UTMⅢ is designed to be less prone to signal disturbance, it can affect measurement results if the noise level is too large.

If the tightening force and torque are not enough, couplings may slip or get disconnected,

and thus, accurate torque cannot be measured. Yet, as far as couplings does not slip, tightening torque and force from couplings will not affect measurement results.

No, you cannot. Products are calibrated before shipping, so please change the setting on indicators to change the full scale.

No. Amplifier is already built into UTMⅢ with voltage output of ±10 V and digital output via RS-485.

Please refer to the conversion chart below and Torque Unit Converter (Opens in a new window).

| N m | N cm | kg m | kg cm | g cm | mN m | |

| N m | 1 | 102 | 0.10197 | 10.197 | 1.0197×104 | 103 |

| N cm | 10-2 | 1 | 1.0197×10-3 | 0.10197 | 1.0197×102 | 10 |

| kg m | 9.8067 | 9.8067×102 | 1 | 102 | 105 | 9.8067×103 |

| kg cm | 9.8067×10-2 | 9.8067 | 10-2 | 1 | 103 | 98.067 |

| g cm | 9.8067×10-5 | 9.8067×10-3 | 10-5 | 10-3 | 1 | 9.8067×10-2 |

| mN m | 10-3 | 0.1 | 1.0197×10-4 | 1.0197×10-2 | 10.197 | 1 |

Maximum rotation speed is 5000 rpm. (UTMⅢ-0.05Nm(R) to 50Nm(R))

If the high accuracy is not required so much, please select the one with the rated capacity that is 1.4 – 2.0 times higher than the estimated nominal torque.

Otherwise, please be careful on overload in case the full range of UTMⅢ needs to be used.

Yes. But, please avoid engine vibration to put external load onto the shaft of UTMⅢ.

With the TC80-D3V, TC80-EIP, TM700, TM320 or TM201, torque and rpm can be measured simultaneously and power can also be displayed.

We are a direct sales manufacturer. You can purchase it directly from Unipulse Japan.

Normally, UTMⅢ can be shipped out in a week or so (after the order is received).

But some of the products might take 2 to 3 weeks.

Additional options will also take a longer time.

UTMⅢ has rigid structure, and it is not likely to be damaged if the product is used properly. In case the product is damaged, it is possible that the damage is critical and too severe to repair. Please contact sales representative for consultation.

It depends on the requirements if we can make special version of UTMⅢ. Please consult with our sales representative for more details.

No. Please confirm and specify what options are needed at the time of order placement.